September 2023 I Volume 44, Issue 3

Interview with Robert J. Arnold

September 2023

Volume 44 I Issue 3

![]()

IN THIS JOURNAL:

- Issue at a Glance

- Chairman’s Message

Conversations with Experts

- Interview with Robert J. Arnold

Technical Articles

- I-TREE A Tool for Characterizing Research Using Taxonomies

- Scientific Measurement of Situation Awareness in Operational Testing

- Using ChangePoint Detection and AI to classify fuel pressure states in Aerial Refueling

- Post-hoc Uncertainty Quantification of Deep Learning Models Applied to Remote Sensing Image Scene Classification

- Development of Wald-Type and Score-Type Statistical Tests to Compare Live Test Data and Simulation Predictions

- Test and Evaluation of Systems with Embedded Machine Learning Components

- Experimental Design for Operational Utility

- Review of Surrogate Strategies and Regularization with Application to High-Speed Flows

- Estimating Sparsely and Irregularly Observed Multivariate Functional Data

- Statistical Methods Development Work for M and S Validation

News

- Association News

- Chapter News

- Corporate Member News

Interviewed by J. Michael Barton, Ph.D., Parsons Corporation

Q: When and how did your career in T&E begin?

A: Upon graduating from the University of Florida in the spring of 1962, I accepted a position with Ling Temco Vought (LTV) in Dallas, TX. I was fortunate to be assigned to work with highly experienced engineers who took me under their wing and guided me as I came up to speed in support of Navy F-8 Crusader and A-7E weapon system programs. My work involved support and analysis of ground and flight tests, culminating with recommendations for aircraft flight limitations. It was an exciting time….from the classroom to a real-world environment.

Q: You spent several years as a contractor. What lured you to civil service and what piqued your interest to join the Air Force as a civilian?

A: Well first of all, ground tests were conducted using LTV facilities in Dallas, and flight tests by using nearby airspace. However, considerable testing on the programs I supported also occurred at Patuxent River, MD. I deployed many times to Pax River to support testing using their unique capabilities…to which we now refer to as Major Range and Test Facility Base (MRTFB). Testing at an active military base opened a whole new world in my eyes. Operating in a real-world mission environment was very rewarding.

Moving forward to 1969, the Air Force acquired the A-7D. In addition to the many types of weapons carried by the A-7E, the Air Force wanted additional weapons to be certified for carriage and release on its version of the airplane. Long story short, the Air Force decided to accomplish testing with two dedicated A-7Ds at Eglin AFB using LTV engineering support. As fate would have it, I happened to walk by my supervisor’s desk and overheard discussion on the need to send an engineer to Eglin to support the test program. No one wanted to go to Eglin! I stepped up to what wound up to be a fantastic career broadening opportunity and got the job. Testing at another active military base provided a unique opportunity to work hand-in-hand with government personnel in planning, executing, analyzing, and reporting results of test missions for almost four years. Important to mention that the LTV support contract mandated that the government wind tunnel (4T) at the Arnold Engineering Development Center (AEDC), Tullahoma, TN be used for all testing vice LTV’s own blow-down tunnel in Dallas. This was a great decision as AEDC’s capabilities were then, and are now, world class and have been a key element of the MRTFB. Looking back these many decades, the growth and nurturing of the MRTFB has been mutually beneficial for the Department of Defense (DoD) and industry. We need to stay the course and continue to improve the technical capabilities of the MRTFB.

In 1974, at the conclusion of the A-7D program, LTV initiated my return to Dallas. Coincidentally, at the same time, A-10 and F-15 weapon compatibility test programs were just getting started at Edwards AFB. Eglin was required to provide Edwards with on-site aircraft/weapon test support. Volunteers were solicited from the technical staff at Eglin, but no-one wanted to relocate from the sands of Florida to the desert. I raised my hand, joined Civil Service, and never looked back. The assignment at Edwards was a highlight of my career and set the stage for my later involvement in analyzing the pros/cons of differing policies, approaches, and capabilities for testing within the Services and at various geographical locations.

Q: What was your role in the test process initially and how did that change over the years?

A: Initially, my role was to execute plans for Developmental Testing (DT) as approved by higher authority “without asking any questions”. With experience, I became emboldened to question the operational utility of test points. For example, many of the weapons on the A-7D called for releasing “unguided bombs” in 60-degree dives. Releasing weapons in such steep dives, with frequent overshoot to even steeper dive angles, caused weapons to float and hit the aircraft. Formal inquiries were ultimately undertaken for the operational user to explain and defend the steep dive requirement. Come to find out (after testing had ended) that dives of not more than 30 degrees were required, but as the requirement went up the chain of the using command, the dive angle was increased by multiple offices to ensure, in their mind, that it would be adequately tested! Another memorable case involved early F-15 flight testing to establish carriage and release of large weapons at very high airspeeds It took an inordinate amount of fuel to reach test conditions with the result that once weapons were released, an immediate return to base was required. It has taken decades to get where we are today, but policy and practice have put us on the road for strong coordination of DT and Operational Testing (OT) as emulated by the buzz words Shift Left (for OT) and Look Right (for DT).

Q: Were there procedures and processes used early-on in your career that you would like to see come back?

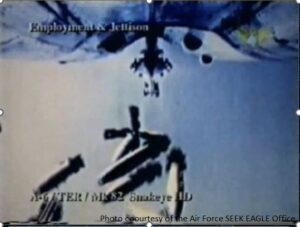

A: For the most part no. In the early 70s the weapons system testing with which I was involved was an inexact science. We had no established guidelines and minimal data banks from earlier test programs. This resulted in our having to constantly extrapolate often limited wind tunnel data or rely on analytical data. We were in an environment where the need to certify new weapons in a multitude of external carriage configurations was “time critical”. We succeeded, but there was a price to be paid for using, in many cases, brute force techniques and we have a “horror film” to prove it, see Figures 1 and 2.

|

|

| Figure 1 Weapon that went on to impact aircraft fuselage. | Figure 2 Weapon-weapon collision and premature extension of retarder fins on one weapon. |

Q: Has your perception of T&E changed as you have served in a spectrum of roles, contractor and civilian, within the Air Force?

A: First and foremost, my perception of T&E as being absolutely vital to the success of a program has not changed one iota. I would be preaching to the choir when I disabuse those who claim that T&E causes schedule delays and cost increases. In large part, these are due to factors related to technological immaturity on the part of the test items themselves. Obviously (from a tester viewpoint), they are better discovered in early development than in production and operational service later.

Q: How did your relationship with ITEA begin?

A: At an Eglin Test Wing meeting in the late 1980s, the Commander mentioned an upcoming technical forum sponsored by ITEA and suggested staff consider attending. I don’t recall specifics of the forum itself, but I do recall being very impressed with the forum’s content along with the opportunity to meet and dialog with attendees from DoD and industry. I joined ITEA at that first forum and have been a member ever since. ITEA functions were then, and continue to be, highly valuable for sharing technical information with the test and evaluation community throughout the country. An early stand-out example was a series of technical forums established and co-sponsored by the Air Force at Eglin and the Navy at Patuxent River to advance the state-of-the-art in aircraft-stores compatibility. The relationships formed at ITEA forums such as this have endured for decades. In mentoring members of the workforce, I continually emphasized the importance of active participation in professional organizations, and ITEA was always at the top of my list.

Q: Over your career, how has technology affected the way we did and currently do testing?

A: Technology has enabled the transformation of how we accomplish testing. On reflection and based on the many programs I’ve supported over the years, we’ve gone from a “fly-fix-fly” modus operandi to “predict-test-analyze”. In this day and age, I am chagrined to relay how frequently we used brute force techniques. For example, we used brute force to establish the maximum extension of the speed brake on the A-7E when releasing weapons from wing pylons at various flight conditions. Speed brake extension was increased in increments until it was hit/damaged by weapons. After landing, the speed brake was repaired, and the process repeated. True story. At the time, this was no big deal. But step forward to today and heads would roll. On the A-10 we used brute force to establish the minimum interval of bombs released from a Multiple Ejection Rack (which carries six bombs with three forward and three back). The goal was to release all bombs in the shortest possible interval without bombs hitting one another. Not a good thing! We dropped a lot of bombs without any analysis other than viewing on-board film and could never safely release all bombs using operationally required low intervals. Classic case of brute force that didn’t work, and which was a waste of time and money. The technological advances in just the last several years alone have essentially transformed the planning and execution of test and evaluation to the point that many programs are surprised when problems arise. While this may always be the case, current processes and procedures enable rapid identification of the cause and cure of problems. And from a big picture perspective, we rarely damage highly expensive test articles as we did when I started my career.

Q: What was the interaction of Program Offices with your test organization? How did that change over the years?

A: From my perspective it was professional and quite positive. At Eglin we had a very deliberative process in which program offices provided their test requirements and desired schedule, and we, in turn, provided them with our cost estimate and planned schedule. We signed a Memorandum of Understanding, funds were transferred, and we were off and running. It really was a smooth process that did not materially change during my tenure.

Q: How would you characterize the health of the T&E workforce, and the ability of industry and the government to attract and retain highly skilled employees?

A: In my view, the overall health of the government workforce is quite good. That said, DoD leadership is actively addressing attraction and retention of personnel with new policies and incentives. It is also fair to say that our government workforce is augmented when and where needed with excellent support from a wide variety of sources (e.g., industry, academia, National Academies, and Federally Funded Research and Development Centers). My only admonition from a government perspective is that when contracting out for support, adequate in-house expertise must be maintained to ensure proper oversight.

Q: How has testing changed as we have lost the military personnel and former military civilians from the workforce?

A: I personally don’t think that loss of military personnel has changed testing to any measurable degree. In my early government service, we did have many junior/company grade officers assigned to our test programs. They later moved on to other career fields and brought with them, particularly in program management assignments, a better understanding of the need for proper test and evaluation planning and execution. Several of these officers went on to achieve flag rank which was most beneficial in securing needed support for modernization of test and evaluation capabilities. But we still have, in my view, adequate military personnel at the right levels within our test organizations. We now also have designated organizations, such as the DoD Test Resource Management Center, to proactively manage modernization of test capabilities, including the need to maintain a world-class workforce.

Q: What advice do you have for people just entering the T&E career field?

A: Listen and learn. Do your best in your current position to meet/exceed job requirements. Be persistent in securing regular feedback on your performance. Work with your supervisor to maintain a training plan. And most important, begin looking for a mentor(s) for long term career planning. Ideally, a mentor should be several levels above your current grade level and not in your chain of command. Finally, seek out and get engaged in multiple professional organizations such as ITEA. It’s highly likely that within such organizations you will find a mentor(s). In my experience, those who are asked to be a mentor are flattered and rarely turn down requests for their support.

Q: Your successful career has centered around Eglin AFB, holding leadership positions as a contractor and later as an Air Force SL. What do you consider to be your career highlights?

A: Let me interject that during the last ten years of my career, I supported the Office of the Secretary of Defense, Director of Operational Test and Evaluation in the Pentagon. By virtue of having exposure to nearly all MRTFBs, I believe I have had some modest influence and success in helping to establish policies and procedures which have resulted in test and evaluation installations collaborating better with one another for the benefit of test customers. In my view, over a period of several decades we have moved from an “independent to exist” mentality (where one installation thought they could do it all without assistance from anyone else) to a “dependent to survive” approach (teaming with others). And today, while still a work in progress, we are moving towards an “interdependent to thrive” model.

Having served on dozens of studies on how best to maintain test and evaluation capabilities within the government (including multiple Base Realignment and Closure studies), I feel that we are on the cusp of moving towards a “range of the future”. For more information on what the future may hold for “range of the future”, I recommend reading the National Academies of Sciences-Engineering-Medicine Consensus Study Report on “Necessary DoD Range Capabilities to Ensure Operational Superiority of U.S. Defense Systems: Testing for the Future Fight” (https://nap.nationalacademies.org/download/26181#).

Q: Do you have any closing remarks or observations?

A: Modernization of test and evaluation capabilities (e.g., infrastructure, hardware, and models and simulation) is high on the radar scope of the Services, the Office of the Secretary of Defense, and The Congress along with the need to preserve mission critical air, land, and sea space. At one time, testing could be conducted within the confines of government ranges. No more, and not even with flight termination devices. For example, proliferation of wind turbines near our test ranges, energy exploration in offshore areas, and many other factors have restricted/impacted testing in real-world environments. Even though we are moving more and more towards conducting a wide variety of testing using indoor facilities/chambers, we need to work in partnership with local communities bordering our bases, elected officials at all levels, and with The Congress to preserve access to needed range space and spectrum.

Last but certainly not least, let me comment on participation of our international partners in many of our test programs. For quite some time in support of the aircraft/stores compatibility program, we had exchange officers from the United Kingdom, Canada, Australia, South Korea, Israel, and Germany working hand in hand with our engineers. The spirit of collaboration was outstanding and was mutually beneficial. In this regard, and in a recent ITEA Journal article, Dr. Mal Tutty (from Australia) commented favorably on his assignment at Eglin (The ITEA Journal of Test and Evaluation 2022; 43 (3): 117-126). Equally beneficial has been international participation in ITEA. We learn so much from our international partners. I’m a firm supporter of expanding involvement in both areas.

Biographies

Robert J. Arnold retired in November 2022 after a distinguished career in T&E that spanned more than sixty years. Internationally recognized and respected, he provided hands-on experience managing and conducting tests at MRTFBs across the nation. As Technical Advisor for the test wing at Eglin AFB, he ensured that long range planning was initiated to meet future joint service T&E needs. He was instrumental in fostering partnerships and cooperation among test centers which increased effectiveness and efficiency of T&E. Overlayed with his dedication to education and mentorship of the workforce, Bob leaves a solid track record of success.

J. Michael Barton, Ph.D., Parsons Fellow, has worked on the Aberdeen Proving Ground since 2001 spending the first 10 years supporting the US Army Developmental Test Command and later the Army Test and Evaluation Command. He joined the Army Research Laboratory Computational and Information Sciences Directorate in April 2015, working in large-scale data analytics, high-performance computing, and outreach to test and evaluation and other ARL stakeholders. Dr. Barton’s entire career is in physics-based modeling and simulation. He spent 6 years as a consultant in the aerospace industry; 12 years as a contractor supporting the Air Force at the Arnold Engineering Developmental Center in Tennessee and the National Aeronautics and Space Administration Glenn Research Center in Ohio; and the first 4 years of his career with The Boeing Company in Seattle. He has worked for Parsons Corporation for the past 8 years. He received Bachelor of Science and Ph.D. degrees in engineering science and mechanics from the University of Tennessee-Knoxville and a Master of Engineering degree in aeronautics and Astronautics from the University of Washington.

- Join us on LinkedIn to stay updated with the latest industry insights, valuable content, and professional networking!